This article is a guest post for our Skill Share series from artisan Rindert Schutten of Schuttenworks, a woodworker, designer, and maker of eco-friendly wooden mason jar and spice jar lids.

“Artisanal Makers” are individuals or small businesses who focus on creating unique and high-quality, handmade items, rather than mass-produced goods. To create these products they often incorporate traditional techniques and skills in their production process. These products can include items like clothing, furniture, jewelry, pottery, and many other types of crafts. Their products are often highly desirable by discerning customers because of the quality, craftsmanship and attention to detail.

Artisanal Makers have many competitive advantages when compared to large established companies. They can easily try out new ideas, respond faster to changing market trends, and are often more sustainable and eco-friendly. These attributes are increasingly important for many of their customers.

Many Artisanal Makers however have to resolve how to implement certain steps in their production process that are very difficult or simply impossible or simply too expensive to do in a small shop setting.

Moreover, since labor is very expensive, they will always be on the lookout for ways to reduce the manual labor since this is directly reflected in the price that they have to ask for their products. Therefore Artisanal Makers will often be on the lookout for automation and/or outsourcing to ensure a price point for their product that is acceptable for their customers while retaining the craftsmanship and artistry of their products.

To find a balance in the production process between what can/should be automated or outsourced and what should really be done by hand is of course different for each Artisanal Maker and product.

Tools like laser cutters, 3-D printers/scanners, CNC machines, are becoming more affordable and home-scale, which makes automating certain steps in their production process more affordable than ever. Moreover with on-demand printing, laser cutting/engraving, and various machining services increasing available, Artisanal Makers have many options to increase the efficiency of their process.

To find the right balance between what to make by hand and what to automate/outsource is very important for your success as an Artisanal Maker, because ultimately it is that balance that determines how your customers value your products and whether you can make living from making your products.

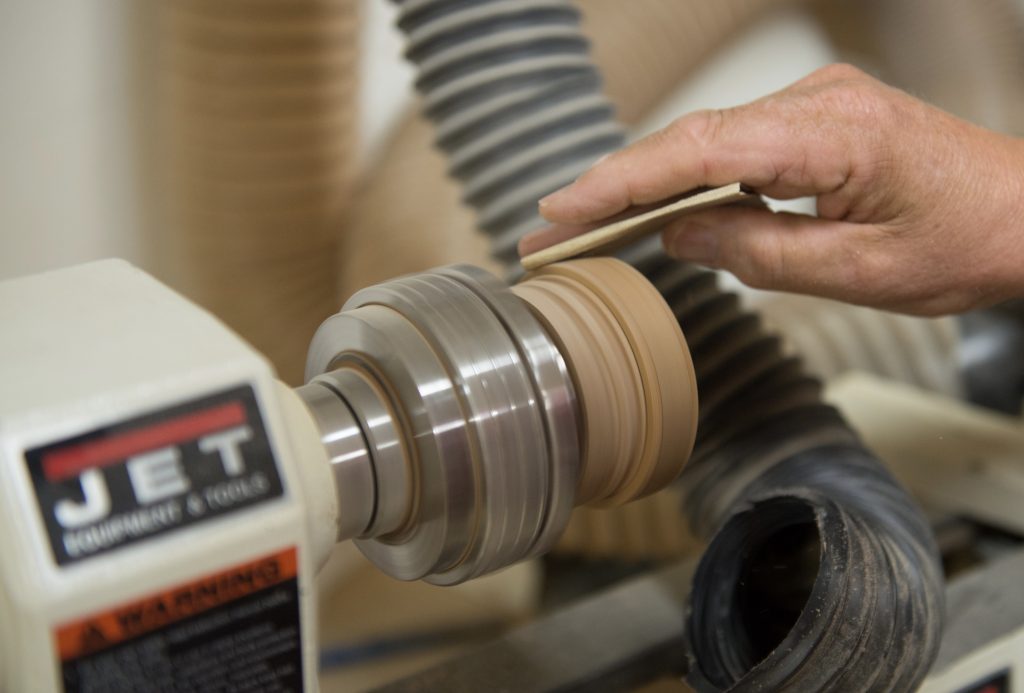

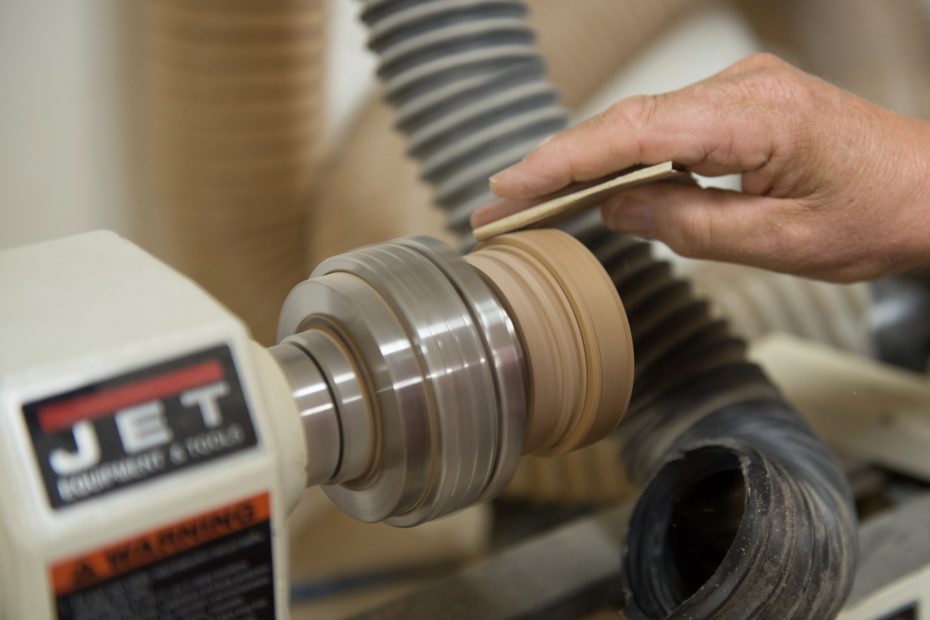

For example. I make wooden screw-top lids for mason jars and spice jars. My customers like them because of the beauty of the wood, their perfect fit on a mason jar, and the craftsmanship by which they are made. In fact the outside of each lid is individually sanded (on a lathe) and finished to a fine low gloss with a food-safe mix of mineral oil and beeswax.

The inside however requires high precision cutting of the pocket and the threading so they fit perfectly on a standard mason jar which is virtually impossible to do by hand (tools), let alone to do it consistently. Moreover to make them leak proof they incorporate a silicon seal which obviously I cannot make myself and have to buy. In fact these are only available from some manufacturers in China.

To sell my lids at a price that customers are willing to pay and for me to make to a reasonable profit of my lids, I have to be very efficient in my production process. My production process is split up in two steps: 1) to create the inside with the threading, and 2) to create a perfect finish for the outside of the lid.

I have chosen to automate the first step by utilizing a CNC machine in my shop. This ensures the required precision of the inside of the lid. Alternatively I could have opted for outsourcing this step and provide a third party with my wood choices and specifications to perform the machining. Since I had an engineering background, and a personal interest in machining my solution to machine the lids in-house was a natural choice. The addition of a small laser cutter to engrave my logo in (the inside of) the lids completes my in-shop automation.

The second step is a manual process, and it is a large part why my customers appreciate my wooden lids. Each lid gets a slight round-over on the router table and is individually sanded on the lathe, so it it is smooth to the touch. Then they are individually finished so the wood grain pops out and are carefully packaged and ready to be shipped to a customer.

In fact, for even more efficiency in my production process I execute the two steps in parallel by working in small batches, i.e while the CNC machine is working on one batch, of say 20 lids, I can manually process the previous batch and/or ship products to my customers.

Of course every Artisanal Maker is different – different skills, different products, different volumes etc., but most of us have to find this balance between what to make ourselves, what to automate in the shop, and what to outsource.

Balancing this in a way so that the artisanal skill and artistry is highlighted in the product while automating/outsourcing those steps that don’t or contribute less to the artisanal value of the product may be key for you to be able to make living as a small Artisanal Maker.

Skill Share Series

This series of guest posts support artisans with skills and tips from experienced artisans and outside experts. Do you have a skill or knowledge to share? Contact us at hi@artisans.coop.

About Artisans Cooperative

We are growing an online handmade marketplace for an inclusive network of creatives: a co-op alternative to Etsy.

Shop the marketplace!

Pingback: The Cost Of Handmade: How Artisans Price Their Work | Artisans Cooperative